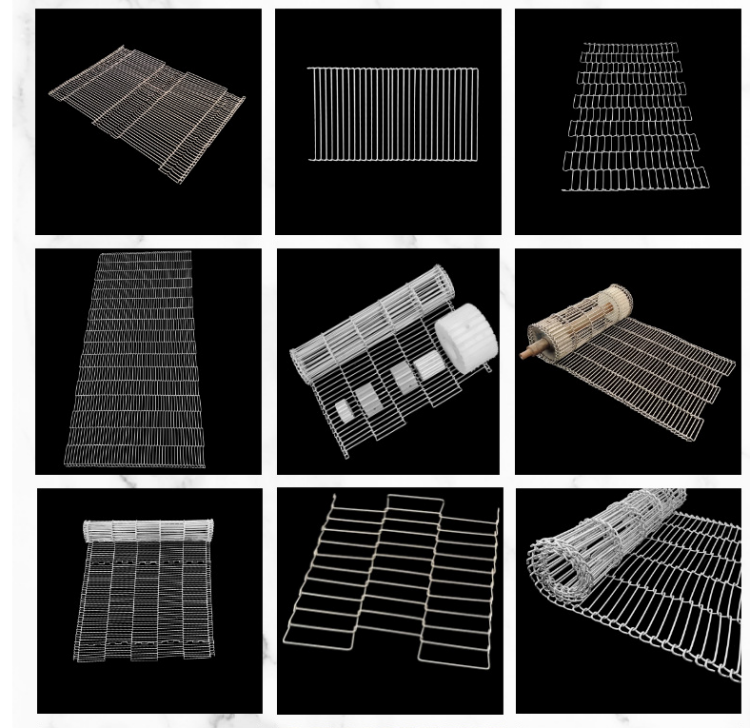

Chocolate Enrober

Wire Belt – High-Efficiency Conveyor Solution for Food Processing Industries Experience superior performance with our advanced Chocolate Enrober Wire Belt, engineered specifically for precision coating, drying, and cooling applications in confectionery and food manufacturing. Designed with a high open structure reaching up to 86% openness, this belt ensures optimal airflow and thermal transfer—ideal for chocolate enrobing, sugar glazing, and surface finishing processes. Whether you're working with delicate pastries, coated candies, or bakery items, this

wire mesh conveyor system delivers consistent results while minimizing product damage. Key Features: - Exceptional Open Design: The robust yet lightweight construction allows maximum ventilation, making it perfect for rapid cooling, dehydration, and heat application in automated production lines. - Positive Drive Mechanism: With sprocket-driven operation and no reliance on friction-based tracking systems, the belt maintains precise movement without slippage—even at high speeds—reducing mechanical wear and operational interruptions. - Enhanced Stability: Engineered with minimal-diameter end rolls and drive rollers, the belt supports fragile products gently, ensuring uniform handling in sensitive environments such as pharmaceuticals, cosmetics, and premium food processing. - Customizable Dimensions & Strength: Available in multiple widths, lengths, and mesh configurations, these belts adapt to diverse industrial needs—from light-duty snack coating to heavy-load chocolate tempering operations. - Reduced Energy Consumption: Compared to traditional woven belts, the lower mass of flat wire and rod network designs significantly decreases power usage, boosting throughput and lowering operating costs over time. - Easy Maintenance & Cost Efficiency: The absence of hidden crevices simplifies cleaning, reduces downtime, and extends service life—resulting in long-term savings across your production cycle. Detailed Description: The Chocolate Enrober Wire Belt is more than just a transport medium—it’s a critical component in modern food automation. Its unique combination of durability, efficiency, and hygiene makes it an essential asset in any facility aiming for peak productivity. Unlike conventional belts that trap debris or require complex maintenance routines, this wire belt design promotes cleanability through its open architecture, which also enhances heat distribution during enrobing and baking stages. Whether used in continuous flow systems or integrated into multi-stage coating lines, the belt supports seamless integration with existing machinery while offering scalability for future expansion. Ideal Applications: This conveyor solution excels in various food processing scenarios including but not limited to: - Chocolate coating and tempering units - Sugar-coated confections (e.g., fruit chews, gummy bears) - Glazed pastries and baked goods - Drying and preheating stations - Pharmaceutical tablet coating and drying - Cosmetic product encapsulation and surface finishing User Feedback: Customers consistently highlight improved product consistency, reduced waste due to better handling, and faster line speeds compared to older belt types. One manufacturer noted a 20% increase in output after switching to this system, citing less downtime and easier sanitation protocols. Another praised the belt’s ability to maintain temperature gradients effectively, leading to more uniform coatings and fewer rejects. Frequently Asked Questions: What makes this wire belt different from standard mesh belts? It offers greater openness, lower weight, and enhanced thermal conductivity, all contributing to higher efficiency and lower energy demands. Is it suitable for high-speed operations? Yes, thanks to its positive drive mechanism and stable rolling elements, it performs reliably even under demanding conditions. How does it improve cleanliness? With no concealed joints or pockets where residue can accumulate, it's easy to rinse down and sanitize quickly between batches. Can it handle heavy loads? Depending on configuration, certain variants are built for heavy-duty use, featuring reinforced joints and optimized tensioning for extended durability. Why choose this over other materials like stainless steel or rubberized belts?

wire belts provide superior heat transfer, better airflow, and longer lifespan with minimal maintenance—especially valuable in industries requiring frequent cleaning cycles and strict hygiene standards.

Product Categories : Wire Belt