High Durability Enrober

Wire Belt for Chocolate Coating and Food Processing Applications This premium 304 stainless steel enrober

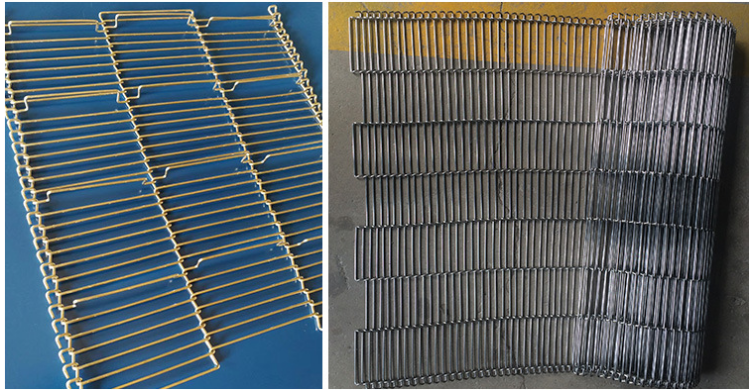

mesh conveyor belt is engineered to deliver exceptional performance in chocolate enrobing, baking, cooling, and drying processes across global food manufacturing facilities. Designed with precision and durability in mind, it ensures consistent product flow while maintaining hygiene standards required by international food safety regulations. As a critical component in automated production lines, this enrober wire belt offers manufacturers a reliable, cost-effective solution that supports high-volume operations without compromising on quality or efficiency. Key Features: - Made from food-grade 304 stainless steel wire for corrosion resistance, longevity, and compliance with FDA and EU food contact standards - Open mesh structure (70–86% openness) enables optimal airflow, ideal for uniform heat distribution during baking, drying, or rapid cooling - Customizable dimensions including width, pitch, and wire diameter to match specific machinery configurations and throughput needs - Lightweight single-layer construction reduces energy consumption and simplifies installation and maintenance - Available in straight or curved configurations to accommodate tight spaces and complex production layouts - Robust loop-wire design enhances tensile strength while allowing flexibility for seamless integration into various conveyor systems Detailed Description: The enrober belt is meticulously crafted using high-tensile stainless steel wires arranged in precise patterns to create a durable yet flexible mesh. Its open architecture allows air circulation essential for thermal processing tasks such as convection baking, dehydration, or chilling chocolate-coated confections. Unlike solid belts, which can trap moisture or contaminants, this

wire mesh conveyor ensures easy cleaning and minimizes microbial buildup—a crucial factor in commercial kitchens and industrial food plants. The belt operates smoothly via sprocket-driven mechanisms, minimizing slippage and ensuring accurate product positioning throughout the process chain. Whether used in chocolate enrobing machines, cooling tunnels, or drying ovens, its adaptability makes it a preferred choice for manufacturers seeking both operational efficiency and regulatory compliance. Ideal Use Cases: This stainless steel enrober mesh belt serves a wide range of applications beyond chocolate coating—including candy production, snack food processing, frozen dessert handling, and baked goods conveyance. It’s particularly effective in environments where temperature control, cleanliness, and continuous operation are paramount. For instance, in automated packaging lines, curved versions of the belt allow products to navigate sharp turns without disruption, enhancing workflow fluidity in compact facilities. Additionally, its ability to withstand repeated thermal cycling makes it suitable for both low-temperature storage zones and high-heat烘烤 areas within a single facility. User Testimonials: "Since installing these enrober belts, our chocolate coating line has seen a 20% reduction in downtime due to fewer maintenance issues." — Production Manager, European Confectionery Manufacturer "We needed a belt that could handle both hot and cold phases efficiently—this one delivers consistently across all stages." — Quality Assurance Lead, North American Bakery Equipment Supplier Frequently Asked Questions: What makes this enrober belt different from standard conveyor belts? Unlike traditional belts made from rubber or plastic, this stainless steel enrober mesh belt provides superior heat resistance, chemical stability, and ease of sanitation, making it ideal for demanding food processing environments. Can I customize the belt size and configuration? Yes, we offer tailored solutions based on your equipment specifications, including custom widths, pitches, and edge profiles to ensure perfect compatibility with existing systems. Is it suitable for use in high-humidity or freezing conditions? Absolutely. The 304 stainless steel material resists rust and maintains structural integrity even under extreme temperature fluctuations, ensuring long-term reliability in diverse climates. How often does the belt require maintenance? Due to its simple design and robust construction, routine inspection every 1–2 months is typically sufficient. Cleaning after each shift is recommended to preserve hygiene and prevent residue buildup.

Product Categories : Wire Belt