Food Grade

Wire Mesh Belt – Durable, Hygienic Conveyor Solution for Industrial Processing Our premium food grade wire mesh belt is engineered to meet the highest standards of safety, performance, and longevity in demanding industrial environments. Designed specifically for food processing, pharmaceuticals, and chemical manufacturing, this conveyor belt delivers consistent operation under extreme conditions while maintaining compliance with global hygiene regulations. Whether you're managing high-temperature baking lines, automated washing systems, or heavy-duty material transport, our

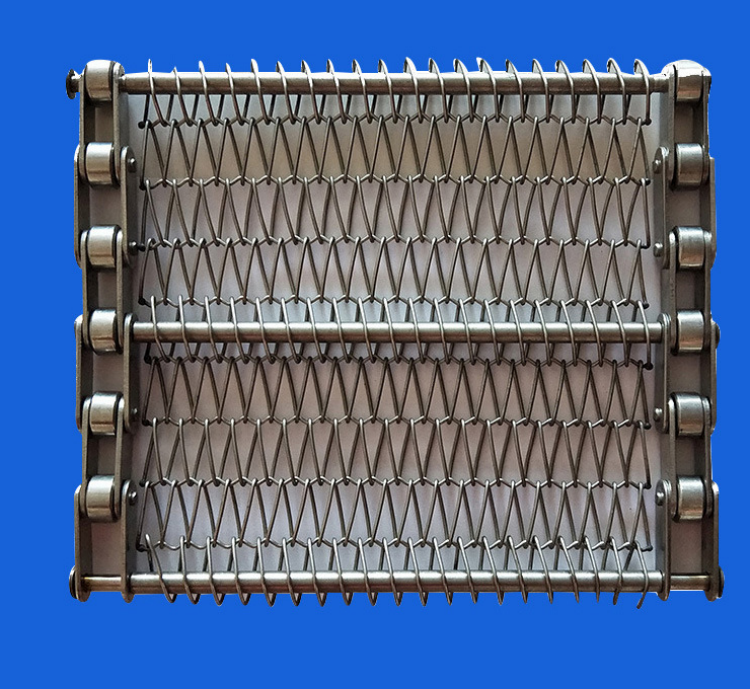

wire mesh belts provide a reliable and efficient solution tailored to your needs. Key Features: - Made from certified food-grade stainless steel (typically 304 or 316L), ensuring no contamination risks - Exceptional resistance to acids, alkalis, chemicals, abrasion, and impact - Operates effectively across a wide temperature range—from freezing to over 500°C—ideal for ovens, coolers, and sterilization units - Seamless design minimizes product buildup and simplifies cleaning - Available in multiple weave patterns (e.g., ladder, diamond, square) for optimized load distribution and airflow - Lightweight yet robust construction supports both light and heavy payloads without deformation Detailed Description: This industrial-grade wire mesh belt combines structural integrity with advanced metallurgical properties to serve as a cornerstone in modern production lines. Unlike traditional rubber or plastic belts, our metal conveyor belts offer superior durability in harsh environments where moisture, heat, and mechanical stress are constant challenges. The precision-welded joints and corrosion-resistant surface ensure long-term reliability even in continuous 24/7 operations. With customizable widths, lengths, and pitch sizes, it integrates seamlessly into existing systems such as tunnel ovens, drying chambers, freeze-drying units, and automated sorting stations. Each belt undergoes rigorous quality control to meet international certifications like FDA, EHEDG, and ISO 22000, making it suitable for use in facilities requiring strict sanitary compliance. Ideal Applications: - Baking and roasting processes in bakeries and snack food plants - Dehydration and drying of fruits, vegetables, and herbs - Pre-cooking and cooling stages in meat and seafood processing - Pharmaceutical tablet coating and drying equipment - Chemical powder handling in controlled atmospheres - Shot blasting and surface treatment applications in metal fabrication Customer Testimonials: "Since switching to this wire mesh belt, our bakery line has seen a 30% reduction in maintenance downtime. It handles hot trays effortlessly and cleans easily between batches." — Food Processing Manager, Europe "The seamless edge design prevents food residue accumulation—a game-changer for our hygienic packaging facility." — Quality Assurance Lead, North America "We've used several brands before, but none match the consistency and wear resistance of this belt during high-speed operations." — Operations Director, Australia Frequently Asked Questions: What makes this belt suitable for food contact applications? It’s constructed from non-toxic, food-safe stainless steel that complies with regulatory standards for direct contact with consumable goods, including those set by the U.S. FDA and EU EC 1935/2004. Can it be used in high-heat environments? Yes, certain grades can withstand temperatures up to 550°C, making them ideal for convection ovens, tunnel furnaces, and thermal processing units. How does it compare to rubber belts in terms of lifespan? Due to its metallic composition, it offers significantly longer service life—often three times more than standard rubber alternatives—especially when exposed to abrasive materials or frequent cleaning cycles. Is customization available for specific machine dimensions? Absolutely. We provide bespoke sizing and configuration options based on your equipment specifications, ensuring perfect fit and optimal functionality. Why choose wire mesh over chain-driven conveyors? Wire mesh belts offer smoother movement, better cleanliness, and reduced noise levels compared to chain systems, especially in sensitive processing areas where product integrity and environmental control matter most.

Product Categories : Wire Mesh Belt