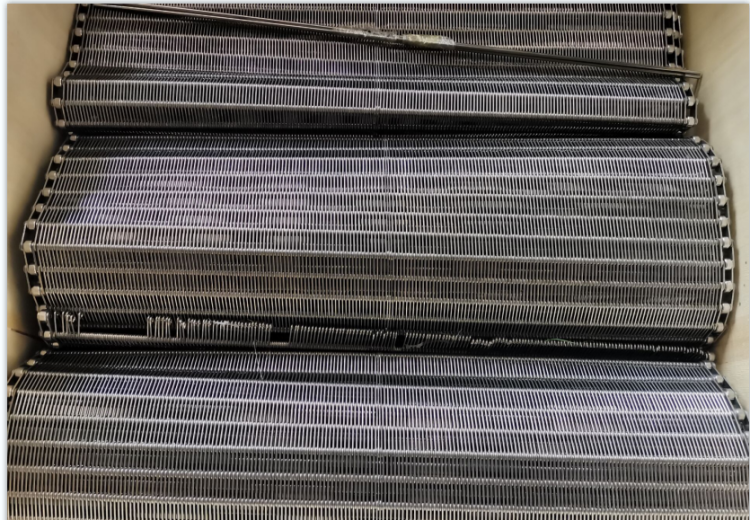

Stainless Steel Eye Link Mesh Belt: High-Performance Conveyor Solution for Precision Industries This stainless steel eye link mesh belt is a premium industrial conveyor component engineered for durability, hygiene, and adaptability across demanding production environments. Designed with precision weaving techniques, it combines round wire mesh with interlocking eye links and connecting rods to create a lightweight yet robust structure that outperforms traditional metal belts in many applications. Ideal for food processing, pharmaceuticals, and electronics manufacturing, this modular belt ensures consistent product handling while maintaining strict cleanliness standards required by global regulatory bodies. Key Features: - Corrosion-resistant 304 or 316 stainless steel construction for long-term reliability - Modular design enables easy installation, maintenance, and customization - Adjustable mesh perforation sizes accommodate various product dimensions - Integrated side and center flights prevent material spillage during inclined or vertical conveyance - Smooth surface finish minimizes product contact points, reducing contamination risks - Excellent airflow and drainage properties enhance cleaning efficiency and reduce downtime Detailed Description: The eye link mesh belt stands out as a versatile solution for industries where both performance and hygiene are critical. Its unique weave pattern—formed by looping round wires into interconnected eye-shaped segments—offers superior flexibility compared to solid or flat belts, allowing smooth operation over pulleys and idlers without deformation. Unlike conventional belts that may trap debris or require frequent replacement, this stainless steel version resists bacterial growth, withstands high temperatures, and maintains structural integrity under continuous use. The inclusion of optional flights (side and center) significantly improves product retention on angled conveyors, making it suitable for applications such as drying, cooling, or sorting delicate items like baked goods, tablets, or printed circuit boards. Additionally, the belt’s open structure allows for efficient heat transfer, liquid drainage, and air circulation—key factors in baking ovens, meat processing lines, and packaging stations. Common Applications: Used extensively in food processing facilities for conveying fruits, vegetables, baked products, and frozen items; in pharmaceutical plants for tablet and capsule transport; and in electronics assembly lines for PCB handling. Also widely adopted in chemical processing, automotive parts washing, and general material handling systems requiring non-stick, non-corrosive surfaces. Its compatibility with automated systems and ability to integrate seamlessly into existing conveyor setups make it a preferred choice for modernized production workflows. Customer Feedback: Users consistently praise its seamless integration into existing systems, noting reduced maintenance needs and improved throughput. One food manufacturer highlighted how switching to this belt eliminated product sticking issues during frying operations, while a pharmaceutical client reported enhanced compliance with FDA and EU GMP guidelines due to the belt’s cleanable surface and lack of crevices where contaminants could accumulate. Frequently Asked Questions: What makes the eye link mesh belt different from flat

wire belts? While flat wire belts offer a smoother surface ideal for fragile materials like glass or semiconductors, the eye link mesh belt excels in airflow, drainage, and flexibility—making it better suited for processes involving moisture, heat, or irregularly shaped products. Is it suitable for high-temperature environments? Yes, depending on the grade of stainless steel used (e.g., 304 or 316), these belts can withstand temperatures up to 800°C, making them perfect for baking, sterilization, and drying applications. How does it improve operational efficiency? Its modular nature allows quick repairs without replacing the entire belt, and its low friction coefficient reduces energy consumption and wear on drive components. Can I customize the mesh size or add flight options? Absolutely—the belt can be tailored to specific product dimensions, with customizable openings ranging from 2mm to 50mm, and side or center flights added based on incline angle and product weight. This stainless steel eye link mesh belt represents a smart investment for any facility seeking reliable, hygienic, and scalable conveying solutions. Whether you're optimizing a food production line or upgrading an electronics assembly system, this belt delivers unmatched versatility, ease of maintenance, and long-term value.

Product Categories : Metal Conveyor Belt