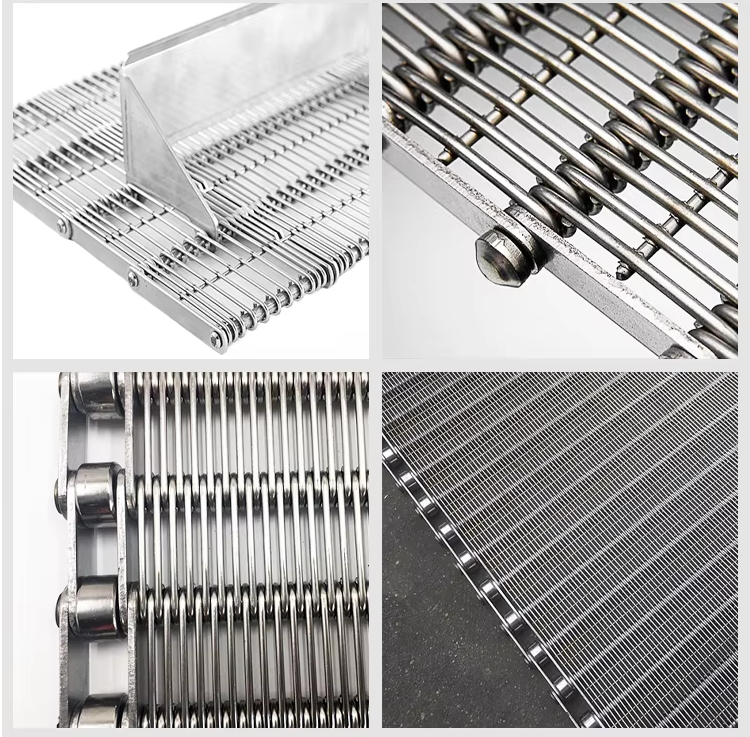

Eye Link Conveyor Belt: Premium Food-Grade Wire Mesh Solution for Industrial Efficiency and Hygiene The Eye Link Conveyor Belt is a high-performance, food-safe material handling system engineered for industries demanding precision, cleanliness, and durability. Designed with advanced wire mesh technology and robust construction, this conveyor belt delivers reliable operation in environments where hygiene standards are non-negotiable—such as food processing, pharmaceutical manufacturing, and packaging facilities. With its FDA-compliant materials and seamless integration into automated systems, the Eye Link solution ensures products remain uncontaminated while maximizing throughput across diverse applications. Key Features: - Food-grade stainless steel wire mesh for compliance with global safety regulations - Durable ring-link design resistant to wear, corrosion, and high-temperature environments - Customizable widths, lengths, and tensioning options for tailored installations - Low maintenance requirements due to optimized engineering and material selection - Smooth surface finish reduces product drag and minimizes spillage or residue buildup - Suitable for both continuous and intermittent conveying tasks Detailed Description: Manufactured using premium-grade alloys and precision welding techniques, the Eye Link Conveyor Belt combines strength with flexibility. Its unique interlocking link structure provides consistent tension distribution, preventing sagging or misalignment even under heavy loads or variable speeds. The open mesh pattern allows for efficient drainage, airflow, and cleaning—critical for maintaining sanitary conditions in food production lines. Unlike traditional belts that require frequent replacement, this model boasts an extended service life thanks to its reinforced links and anti-friction coating. Whether transporting raw ingredients, baked goods, frozen items, or packaged consumer products, the belt maintains stable performance without compromising on safety or speed. This industrial conveyor system supports multiple load types—from lightweight pouches to dense cartons—making it ideal for multi-product lines. Its modular design enables easy installation, repair, and reconfiguration, reducing downtime and increasing operational uptime. Furthermore, the belt’s ability to withstand harsh cleaning agents such as caustic solutions or steam sanitization makes it a preferred choice in regulated industries like meat processing, dairy, and pharmaceuticals. Use Cases: Ideal for bakeries, snack manufacturers, seafood processors, fruit and vegetable packers, and cold storage logistics centers. Also widely adopted in pharmaceutical plants for tablet and capsule conveyance, and in e-commerce fulfillment centers for parcel sorting. The Eye Link Conveyor Belt excels in any setting requiring hygienic, efficient, and scalable material transport. Customer Feedback: Users consistently praise the belt's reliability in high-volume operations, noting reduced maintenance costs and improved workflow consistency. One client in the U.S. reported a 30% decrease in unplanned stops after switching from rubber to

wire mesh belts. Another European food processor highlighted how the belt’s smooth surface prevented product damage during automated packing, leading to fewer customer complaints and higher quality scores. Frequently Asked Questions: What makes the Eye Link Conveyor Belt suitable for food processing? Its food-grade stainless steel composition meets international hygiene standards (e.g., NSF, EHEDG), ensuring no leaching of harmful substances into food products. The open mesh also facilitates thorough cleaning and prevents bacterial growth. Can it handle different temperatures? Yes, the belt performs reliably in both freezing and hot environments—from -20°C to +150°C—making it adaptable to ovens, blast freezers, and pasteurization units. Is customization available? Absolutely. We offer bespoke configurations including custom dimensions, link spacing, and motorized drive systems to match specific facility layouts and process needs. How does it compare to rubber or PVC belts? Unlike conventional belts, the Eye Link model offers superior resistance to oil, heat, and abrasion. It also eliminates the risk of contamination from degraded rubber particles, which can be critical in sensitive sectors like infant formula or sterile medical device assembly.

Product Categories : Metal Conveyor Belt