Food Grade

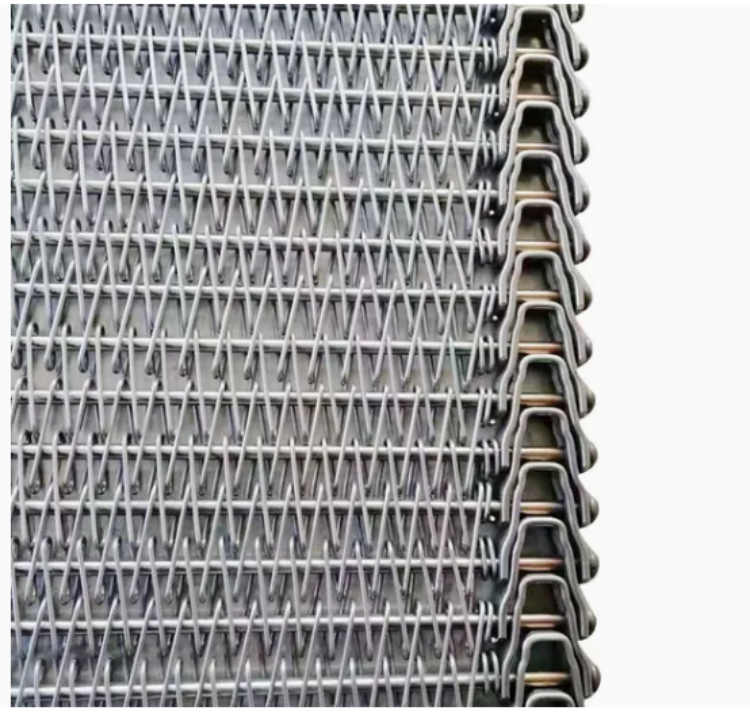

Wire Conveyor Belt – Durable, Customizable, and Ideal for Industrial Food Processing When it comes to reliable material handling in demanding environments—especially where hygiene, precision, and durability are critical—the food grade wire conveyor belt stands out as a top-tier solution. Designed specifically for the food and beverage industry, this high-performance belt ensures consistent product movement across complex workflows, from cooking and cooling to drying and packaging. Engineered with food-safe materials and modular design principles, it meets stringent global standards such as FDA, EHEDG, and 3A certifications, making it suitable for use in bakeries, meat processing plants, confectionery lines, and more. Key Features: - Positive drive system for accurate timing and controlled motion - Stainless steel or carbon steel chain options for corrosion resistance or heavy-duty strength - Modular wire mesh construction for easy cleaning and maintenance - Customizable dimensions (up to 6.5 meters wide) and configurations - Available with edge treatments: welded, laddered, or U-pin selvage - Compatible with accessories like side plates, flights, guard rails, and support rods Detailed Description: This wire conveyor belt is built for versatility and longevity in industrial settings where both efficiency and safety matter. The balanced weave mesh design offers uniform load distribution, minimizing sagging or deformation under heavy payloads—ideal for transporting frozen goods, baked items, or wet products that require drainage. Unlike traditional rubber belts, which can degrade when exposed to oils, water, or extreme temperatures, the wire mesh version maintains structural integrity even in harsh conditions such as quenching baths, steam tunnels, or deep fryers. Its open structure allows air circulation and liquid runoff, reducing contamination risks and improving sanitation compliance. Whether you're managing inclined conveyance, long-distance transport, or high-speed operations, these belts deliver smooth, uninterrupted performance thanks to their chain-driven mechanism. With customizable pitch sizes, wire diameters, and tensioning systems, manufacturers can tailor each belt to match specific production needs without compromising on quality or throughput. Use Cases: Perfect for applications involving hot or cold processing, including ovens, blast freezers, blanchers, and chillers. Commonly used in automated lines for pasta, snacks, seafood, dairy products, and ready-to-eat meals. Also widely adopted in pharmaceuticals and cosmetics for sterile handling of tablets, tubes, and jars due to its non-reactive surface and easy-to-sanitize properties. Customer Testimonials: "Switching to this

Wire Belt improved our throughput by 20% while reducing downtime from cleaning and maintenance." "Our team appreciated how quickly we could adapt the belt width and add cross flights for securing irregular-shaped items during baking." "The stainless steel version has held up perfectly in our seafood processing line—even after years of exposure to saltwater and acidic marinades." Frequently Asked Questions: What makes a wire conveyor belt food-grade? It’s constructed using certified materials like food-safe stainless steel or passivated alloys that resist rust, chemical leaching, and microbial growth, ensuring safe contact with consumable products. Can I customize the belt for my specific machine? Yes—options include adjustable spiral and rod pitches, various edge finishes, and integration with existing drive systems for seamless retrofitting. How do I maintain the belt’s hygiene? The open mesh design prevents debris buildup, and most models allow for quick disassembly and rinsing. Regular inspection and lubrication of chains ensure optimal lifespan. Is it suitable for inclined runs? Absolutely—it provides positive traction and stability even at steep angles, eliminating slippage or product drop-off common with belt-driven alternatives. In summary, the food grade wire conveyor belt combines robust engineering with flexibility, offering unmatched reliability for modern food processing facilities worldwide. From small-scale operations to large-scale automation, it delivers consistent performance, regulatory compliance, and long-term value.

Product Categories : Wire Conveyor Belt