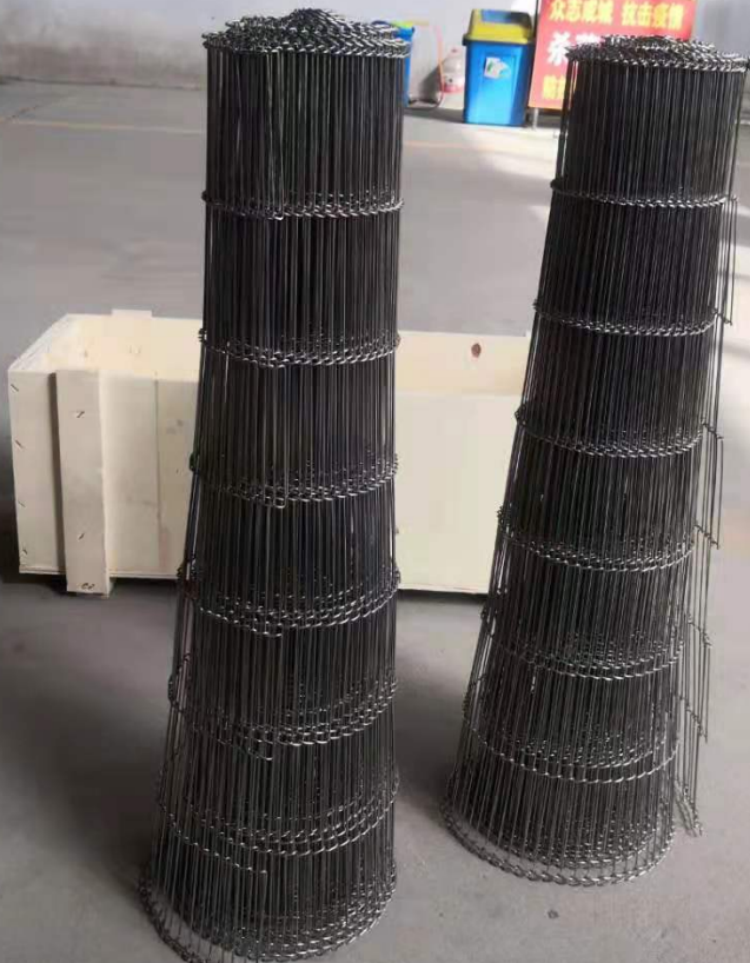

flat flex belts,

wire mesh conveyor Belts, and Wire Conveyor Belts are critical components in modern material handling systems, widely used in food processing, electronics, and thermal

applications. Proper maintenance ensures longevity, efficiency, and safety. Below are key practices tailored for each belt type, with cross-cutting strategies to optimize performance.

1. Cleaning & Sanitation

- Flat Flex Belts: Use soft brushes and food-grade cleaners to prevent debris buildup in their open ladder structure. Avoid abrasive tools to protect nickel-coated surfaces.

- wire mesh belts: Employ high-pressure washers for mesh gaps, ensuring no residue remains in interwoven wires. For food-grade belts, sanitize with mild detergents.

- Wire Conveyor Belts: Regularly inspect for rust; wipe down with dry cloths post-cleaning to avoid moisture retention.

2. Tension & Alignment

- Flat Flex: Adjust tension via sprockets to prevent slippage. Minimal bending radius (3x belt thickness) avoids edge fatigue.

- Wire Mesh: Align chains periodically to prevent lateral drift. Check cross-rod welds for cracks.

- wire belts: Ensure even distribution across pulleys; misalignment causes uneven wear on wire strands.

3. Lubrication & Corrosion Control

- Apply dry film lubricants to Flat Flex sprockets to reduce friction. For high-temperature environments (>400°F), use graphite-based coatings.

- Wire Mesh and Wire Belts in corrosive settings (e.g., salt processing) benefit from 316 stainless steel alloys and periodic passivation treatments.

4. Inspection Protocols

- Daily: Check for broken wires, loose edges, or misaligned links.

- Monthly: Measure belt elongation (Flat Flex) or mesh distortion (Wire Mesh). Replace if stretch exceeds 2%.

- Annually: Audit drive systems (gears, pulleys) for wear compatibility.

5. Environmental Adaptation

In freezing conditions, pre-heat belts to avoid brittleness. For oven applications, use PTFE-coated Flat Flex Belts to resist heat degradation.