The

honeycomb conveyor belt: A Versatile, High-Performance Solution for Industrial Material Handling Overview The

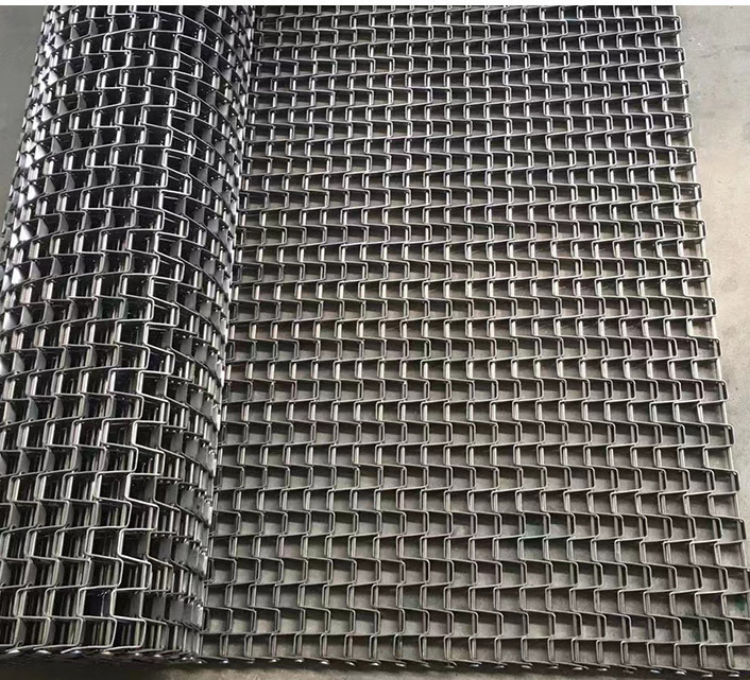

honeycomb conveyor belt is a premium-grade, durable material transport system engineered for maximum efficiency across diverse industrial environments. Also known as horseshoe or flat wire conveyor belts, this solution stands out due to its adaptability and robust design—making it ideal for applications ranging from food processing and cooling systems to riverbed cleaning and harvesting operations. With customizable baffles, multiple material options, and compatibility with various sprocket configurations, the belt delivers reliable performance tailored to specific operational needs worldwide. Key Features - Customizable Baffles for Controlled Material Flow: Enhance directional control by adding baffles that guide product movement, ensuring consistent throughput and minimizing spillage. - Wide Range of Material Options: Available in high-quality stainless steel, carbon steel, and galvanized steel, each offering unique corrosion resistance, strength, and longevity suited to different environmental demands. - Enhanced Stability Through Sprocket Integration: Compatible with precision-engineered sprockets designed to meet exact specifications, supporting smooth operation and long-term durability under heavy-duty conditions. - Industry-Grade Flexibility: Designed for seamless integration into washing lines, drying tunnels, chilling units, and even agricultural harvesting equipment. - Scalable Design for Diverse Applications: Suitable for both compact production setups and large-scale industrial processes, thanks to its modular construction and wide-ranging application support. Detailed Description This innovative

Honeycomb Belt combines structural integrity with functional versatility, making it a preferred choice among global manufacturers seeking efficient, low-maintenance solutions. The belt’s open-cell structure allows for superior airflow and drainage—ideal for wet or sticky materials—while maintaining load-bearing capacity and dimensional stability. Its surface texture supports friction-based handling without damaging delicate products, reducing downtime and increasing throughput. Whether used in food processing facilities requiring hygienic compliance or in manufacturing plants needing rugged, chemical-resistant components, the belt adapts seamlessly. It can be customized with adjustable baffles to manage flow rates, prevent jamming, and ensure uniform distribution across conveyance paths. Furthermore, the ability to integrate with specialized sprockets ensures optimal tensioning and alignment, particularly in automated systems where precision matters. Unlike conventional belts, this design resists deformation over time and offers excellent wear resistance—even in harsh conditions like high humidity, temperature fluctuations, or abrasive substances. Applications Engineered for broad utility, the honeycomb belt excels in numerous sectors including food processing (e.g., fruit sorting, vegetable washing), pharmaceuticals (for sterile packaging lines), agriculture (lettuce harvesting, seed cleaning), and waste management (riverbed debris removal). In cooling chambers, it prevents product stacking while allowing air circulation; in drying systems, it minimizes material loss through optimized airflow; and in tough outdoor tasks such as landfill clearing or mining, its reinforced frame withstands extreme stress. This makes it an indispensable asset for any facility prioritizing productivity, safety, and sustainability. User Testimonials “Since implementing the honeycomb belt in our lettuce packing line, we’ve seen a 30% reduction in product damage during transit.” — Operations Manager, European Agri-Food Facility “Our team was impressed by how easily we could modify the belt with custom baffles to fit our unique bottling process. No more manual adjustments!” — Production Supervisor, North American Beverage Manufacturer “This is the only conveyor belt that survived three years of continuous use in our humid meat processing plant without degradation.” — Maintenance Lead, Global Meat Processing Company Frequently Asked Questions What makes the honeycomb belt different from standard flat

wire belts? Unlike traditional designs, the honeycomb configuration provides enhanced airflow, reduced clogging risk, and better grip on irregular items, especially beneficial in wet or granular material handling. Can it be adapted for food-safe environments? Yes—it’s available in food-grade stainless steel variants that comply with international hygiene standards, enabling safe use in direct contact with consumables. How does it handle tough tasks like riverbed cleaning? Its strong, interlocking mesh structure and corrosion-resistant finish allow it to operate reliably in muddy, rocky, or saline environments without frequent replacement. Is installation complex? No—it’s modular and compatible with existing conveyor frames, allowing quick retrofitting without major infrastructure changes. What maintenance does it require? Minimal. Regular inspection and occasional lubrication of sprockets are recommended, but the belt itself requires no frequent replacements due to its resilient construction.

Product Categories : Honeycomb Belt