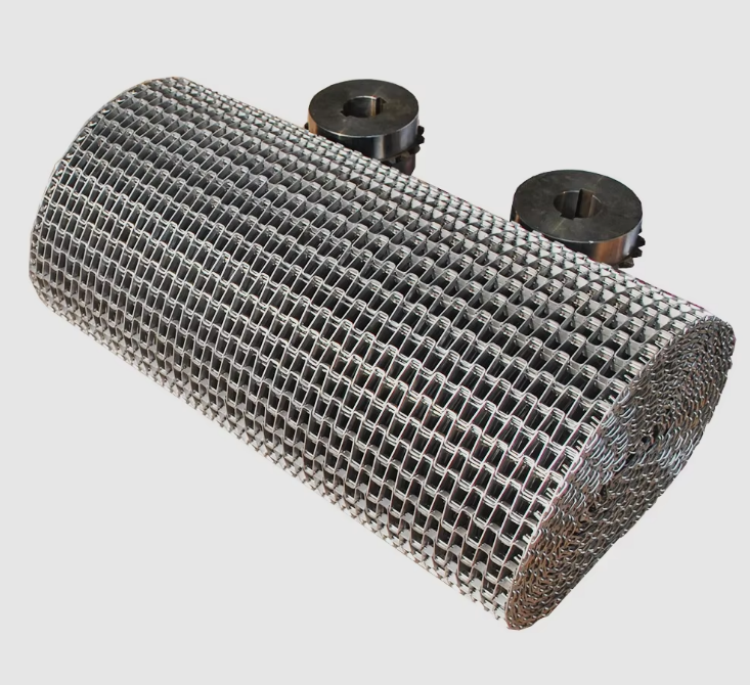

mesh conveyor belt for industrial applications The honeycomb mesh conveyor belt, also known as a

flat wire conveyor belt or lattice-style belt, is an engineered solution designed for high-performance material handling across diverse industries. This robust and flexible system combines structural integrity with adaptability, making it ideal for environments that demand durability, cleanliness, and consistent operation under heavy loads. With its distinctive honeycomb pattern formed by interwoven flat wires and round rods, this belt offers superior strength-to-weight ratio while maintaining excellent airflow and drainage properties—critical in food processing, drying, cooling, and heat treatment processes. Key features of the

honeycomb conveyor belt include welded edge construction for enhanced stability and longevity, as well as optional clinched edges for specialized configurations. Available in multiple pitch sizes and customizable dimensions, these belts can be tailored to fit unique operational needs—from narrow widths for precision conveyance to wide formats for bulk transport. The belt’s modular design allows for easy maintenance, replacement, and integration into existing systems without downtime. Constructed from premium materials such as high-carbon steel, galvanized steel, stainless steel (including grades 304 and 316), and other corrosion-resistant alloys, the honeycomb mesh belt ensures long-term reliability even in harsh conditions. Whether used in high-temperature ovens, freezing chambers, or chemical environments, the belt maintains dimensional accuracy and resistance to deformation. Additional options like side plates, flights, or custom coatings further expand functionality—for example, anti-static finishes for electronics manufacturing or food-grade surfaces for compliance with global hygiene standards. This type of conveyor belt excels in applications requiring efficient product flow, minimal friction, and easy cleaning. It supports both horizontal and inclined conveying, making it suitable for automated packaging lines, pharmaceutical drying units, bakery equipment, and metalworking operations. Its open structure reduces product buildup and facilitates air circulation, which is essential in drying tunnels, curing ovens, and sterilization processes where uniform temperature distribution matters most. Users report exceptional performance in continuous-duty settings, praising the belt's quiet operation, low wear on rollers, and consistent alignment over time. Many operators note reduced maintenance costs due to the absence of chain-driven components and the ease of replacing individual sections instead of entire belts. In food processing plants, the smooth surface and non-porous design prevent bacterial growth, meeting international safety benchmarks such as FDA and EHEDG compliance. Common questions often revolve around load capacity, maximum operating temperature, and compatibility with existing drive systems. Most models support up to 50 kg/m² of evenly distributed weight and can withstand temperatures ranging from -40°C to +800°C depending on material selection. Installation typically requires standard sprocket-driven mechanisms and is compatible with most industrial motorized conveyor setups. For optimal results, regular inspection and lubrication of moving parts are recommended—but overall, the honeycomb mesh belt delivers years of dependable service with minimal intervention. In summary, the

honeycomb conveyor belt stands out as a versatile, durable, and highly customizable component for modern industrial automation. Whether you're upgrading your production line or designing a new system, this belt offers the perfect blend of innovation, efficiency, and adaptability to meet evolving industry demands worldwide.

Product Categories : Honeycomb Belt